Deskripsi Produk:

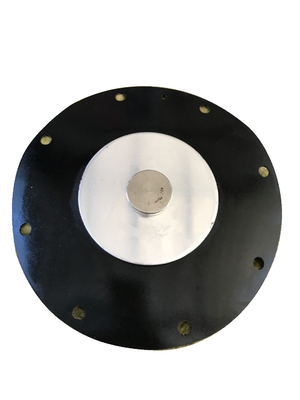

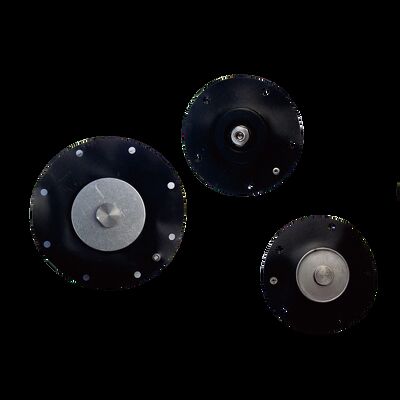

Diafragma Katup Solenoid adalah komponen penting yang dirancang untuk memastikan kinerja dan keandalan yang optimal dalam berbagai aplikasi kontrol fluida. Dibuat khusus untuk memenuhi kebutuhan sistem Katup Solenoid Mesin Kopi serta rakitan Koil Katup Solenoid Hidrolik, diafragma ini menawarkan sifat penyegelan dan daya tahan yang sangat baik. Ia beroperasi secara efisien dalam rentang tekanan 0 hingga 10 Bar, sehingga cocok untuk lingkungan bertekanan rendah dan sedang.

Salah satu fitur unggulan dari Diafragma Katup Solenoid ini adalah kemampuannya untuk mempertahankan penyegelan yang baik dalam berbagai kondisi tekanan. Kemampuan penyegelan sangat penting dalam mencegah kebocoran, memastikan bahwa katup solenoid berfungsi dengan mulus tanpa kehilangan fluida atau tekanan. Hal ini sangat penting dalam aplikasi Katup Solenoid Mesin Kopi, di mana presisi dan kebersihan sangat penting. Bahan dan desain diafragma menjamin segel yang rapat, berkontribusi pada efisiensi dan umur panjang keseluruhan sistem katup.

Diafragma memiliki ketebalan 1,5 mm, yang memberikan keseimbangan sempurna antara fleksibilitas dan kekuatan. Ketebalan ini memungkinkan diafragma untuk menahan tekanan mekanis yang diberikan selama pengoperasian katup sambil mempertahankan elastisitas yang diperlukan untuk merespons perubahan tekanan dengan cepat. Akibatnya, Diafragma Katup Solenoid memberikan kinerja yang konsisten, mengurangi keausan pada komponen terkait dan meminimalkan persyaratan perawatan.

Dengan ukuran lubang 3/4 inci, diafragma ini kompatibel dengan berbagai katup solenoid yang digunakan dalam aplikasi komersial dan industri. Ukuran lubang 3/4 inci memastikan kapasitas aliran yang memadai, memfasilitasi kontrol dan pengelolaan fluida yang efisien. Baik digunakan dalam pengaturan Katup Solenoid Mesin Kopi atau diintegrasikan ke dalam sistem Koil Katup Solenoid Hidrolik, ukuran diafragma mendukung laju aliran dan responsivitas yang optimal.

Kemampuan rentang tekanan 0 hingga 10 Bar membuat Diafragma Katup Solenoid ini sangat serbaguna. Ia dapat digunakan di berbagai lingkungan, mulai dari mesin kopi rumah tangga yang membutuhkan kontrol tekanan yang presisi dan lembut hingga sistem hidrolik yang lebih menuntut di mana fluktuasi tekanan adalah hal yang umum. Kemampuan diafragma untuk berkinerja andal di seluruh spektrum tekanan yang luas ini menyoroti kemampuan beradaptasi dan kekokohannya.

Dalam mesin kopi, katup solenoid memainkan peran penting dalam mengelola aliran air dan uap. Diafragma Katup Solenoid memastikan bahwa katup membuka dan menutup dengan presisi, mempertahankan tekanan yang sempurna untuk penyeduhan. Hal ini menghasilkan kualitas kopi yang konsisten dan efisiensi mesin. Sifat penyegelan diafragma yang baik mencegah kebocoran yang dapat menyebabkan masalah kinerja atau kerusakan pada komponen internal mesin.

Demikian pula, dalam aplikasi hidrolik, diafragma diintegrasikan dengan Koil Katup Solenoid Hidrolik untuk mengontrol pergerakan fluida hidrolik. Kontrol ini sangat penting untuk mengoperasikan mesin dan peralatan hidrolik secara akurat dan aman. Daya tahan dan efisiensi penyegelan diafragma membantu menjaga integritas sistem, mencegah kontaminasi dan kehilangan fluida, yang dapat membahayakan kinerja sistem hidrolik.

Secara keseluruhan, Diafragma Katup Solenoid adalah komponen yang sangat andal dan efisien yang dirancang untuk memenuhi kebutuhan aplikasi Katup Solenoid Mesin Kopi dan Koil Katup Solenoid Hidrolik. Toleransi tekanannya hingga 10 Bar, dikombinasikan dengan ukuran lubang 3/4 inci dan ketebalan 1,5 mm, memastikan bahwa ia dapat menangani berbagai tuntutan operasional. Kualitas penyegelan yang baik meningkatkan keandalan sistem, mengurangi perawatan, dan memperpanjang umur rakitan katup. Baik dalam peralatan dapur atau sistem hidrolik industri, diafragma ini memberikan kinerja dan daya tahan yang diperlukan untuk pengoperasian yang mulus.

Fitur:

-

Nama Produk: Diafragma Katup Solenoid

-

Cocok Kompatibel: Katup Pneumatik Katup Solenoid ASCO

-

Bahan: NBR (Karet Nitril Butadiena) untuk daya tahan dan fleksibilitas

-

Rentang Tekanan: 0 hingga 10 Bar, cocok untuk berbagai aplikasi

-

Ketebalan: 1,5 mm memastikan kinerja optimal

-

Ketahanan Korosi Tinggi untuk penggunaan jangka panjang

-

Ideal untuk aplikasi Katup Solenoid Mesin Kopi

-

Bekerja secara efisien dengan sistem Koil Katup Solenoid Hidrolik

-

Suku cadang pengganti yang sempurna untuk perawatan Katup Solenoid Mesin Kopi

Parameter Teknis:

|

Cocok

|

Katup Pneumatik Katup Solenoid ASCO

|

|

Rentang Suhu

|

-20°C Hingga 80°C

|

|

Tegangan Operasi

|

12V / 24V / 110V / 220V (tergantung Pada Katup Solenoid)

|

|

Ukuran Lubang

|

3/4 Inci

|

|

Ketebalan

|

1,5 Mm

|

|

Prinsip Kerja

|

Dioperasikan Pilot

|

|

Tipe Koil

|

Solenoid

|

|

Tipe Pemasangan

|

Sekrup

|

|

Rentang Tekanan

|

0 Hingga 10 Bar

|

|

Ketahanan Korosi

|

Ketahanan Korosi Tinggi

|

Aplikasi:

Diafragma Katup Solenoid HONGUM adalah komponen penting yang dirancang agar sesuai dengan Katup Pneumatik Katup Solenoid ASCO, memastikan pengoperasian yang andal dan efisien di berbagai aplikasi. Bahan diafragma karet nitrilnya yang unggul menawarkan elastisitas dan daya tahan yang sangat baik, yang berkontribusi pada sifat penyegelan yang baik dan ketahanan korosi yang tinggi. Hal ini membuat diafragma sangat cocok untuk lingkungan di mana paparan kelembaban, minyak, dan zat korosif lainnya adalah hal yang umum.

Salah satu kesempatan aplikasi utama untuk Diafragma Katup Solenoid HONGUM adalah pada mesin kopi yang dilengkapi dengan katup solenoid. Kemampuan diafragma untuk mempertahankan penyegelan yang baik di bawah berbagai tekanan memastikan kinerja yang konsisten pada katup solenoid mesin kopi, yang sering beroperasi di bawah kondisi yang berfluktuasi. Hal ini menghasilkan kontrol yang tepat terhadap aliran air dan pelepasan uap, meningkatkan kualitas dan keandalan proses penyeduhan kopi.

Dalam pengaturan industri, diafragma banyak digunakan dalam rakitan katup solenoid bertekanan tinggi. Dengan rentang tekanan kerja 0-10 Bar, ia sangat cocok untuk mengontrol aliran fluida dalam sistem hidrolik dan pneumatik. Kompatibilitasnya dengan sistem koil katup solenoid hidrolik memungkinkannya untuk menahan variasi tekanan yang intens sambil mempertahankan kinerja penyegelan yang stabil. Ini menjadikannya pilihan ideal untuk aplikasi seperti jalur manufaktur otomatis, sistem kontrol fluida, dan mesin tugas berat.

Selain itu, ketahanan korosi tinggi diafragma HONGUM membuatnya sempurna untuk digunakan di lingkungan di mana paparan bahan kimia lazim. Baik di pabrik pengolahan air, pemrosesan kimia, atau sistem kontrol pneumatik, diafragma memberikan penyegelan yang andal yang memperpanjang umur rakitan katup solenoid. Daya tahannya mengurangi frekuensi perawatan dan meminimalkan waktu henti, menawarkan efisiensi operasional yang hemat biaya.

Secara keseluruhan, Diafragma Katup Solenoid HONGUM adalah produk serbaguna dan tahan lama yang dirancang untuk berbagai skenario termasuk katup solenoid mesin kopi, katup solenoid bertekanan tinggi, dan aplikasi koil katup solenoid hidrolik. Penyegelan yang sangat baik, konstruksi karet nitril yang kuat, dan ketahanan terhadap korosi menjadikannya komponen yang sangat diperlukan untuk memastikan kinerja katup yang optimal di berbagai industri.

Dukungan dan Layanan:

Produk Diafragma Katup Solenoid kami didukung oleh dukungan dan layanan teknis yang komprehensif untuk memastikan kinerja dan umur panjang yang optimal. Kami menyediakan panduan instalasi terperinci, manual pemecahan masalah, dan instruksi perawatan untuk membantu Anda di setiap tahap siklus hidup produk.

Untuk meningkatkan keandalan, tim teknis kami menawarkan konsultasi ahli tentang pemilihan bahan dan konfigurasi diafragma yang sesuai untuk persyaratan aplikasi spesifik Anda. Kami juga menyediakan layanan kustomisasi untuk memenuhi kondisi operasional yang unik.

Selain itu, kami menawarkan layanan perbaikan dan penggantian untuk meminimalkan waktu henti dan memperpanjang masa pakai diafragma katup solenoid Anda. Tim jaminan kualitas kami melakukan pengujian dan inspeksi yang ketat untuk menjamin standar dan kepatuhan produk.

Sesi pelatihan dan webinar reguler tersedia untuk membuat staf Anda tetap mendapatkan informasi terbaru tentang praktik terbaik dan kemajuan terbaru yang terkait dengan teknologi diafragma katup solenoid.

Komitmen kami adalah untuk memberikan dukungan yang tepat waktu dan efektif, memastikan sistem Anda beroperasi secara efisien dan aman dengan solusi diafragma katup solenoid kami.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!